With over 20 years of successful experience, we have been providing high-quality services to our customers and suppliers.

Get a Quote

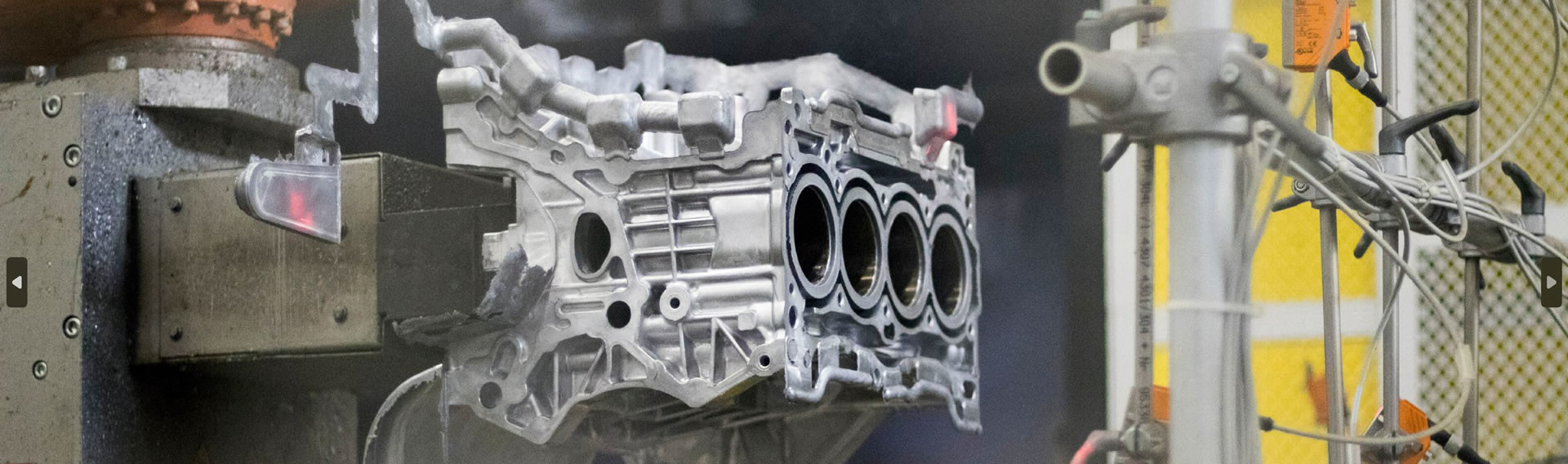

Die Casting Parts

| Production Capabilities |

Aluminum Die Cast with technologies of Vacuum, Local Squeezing, Jet Cooling, and Low Speed Injection, CNC Machining, Pressure Test, Shot Blast, Assembly, Impregnation, Passivation, Powder Coat, Anodizing, Spray Painting, E-coat.

|

| Design Capability |

Die-Cast Simulation, Tooling Design, Tooling Manufacturing, Strength Analysis

|

| Production Equipment |

Die cast machines ranging from 250-9000Ton (Brand such as, LK, YIZUMI, TOYO, Buhler, UBE, TOSHIBA etc.) Die-casting machines with automatic cell and error proof system, vacuum system available for porosity free parts. Center melting furnaces, Auto temperature controll holding furnace. Strong machining capacity, Horizontal/ Vertical CNC (4 Axis or 5 axis available), CNC lathe, Turning and Milling center, passby washing, Ultrasonic cleaning, water jet deburring to meet different cleanliness requirement.

|

| Inspection Equipment |

CMM, X-Ray Equipment, Spectrograph, Cylindricity Tester, Profile Meter, Leak Test Equipment, Cleanliness Analysis Lab, 3D scanners.

|

|

Weight

|

Typical grams to 40kg. Maximum part weight 160kg (9000T die-casting machine)

|

| Material |

A380, A383, A360, B390, ADC14, ADC12, ADC10, EN AC 46000, 44300, 43400, etc.

|

|

Quality

|

ISO 9001, IATF 16949, ISO14001, etc.

|

Our services cover all industries and reach all parts of the world.We can make all kinds of products for you according to your design.